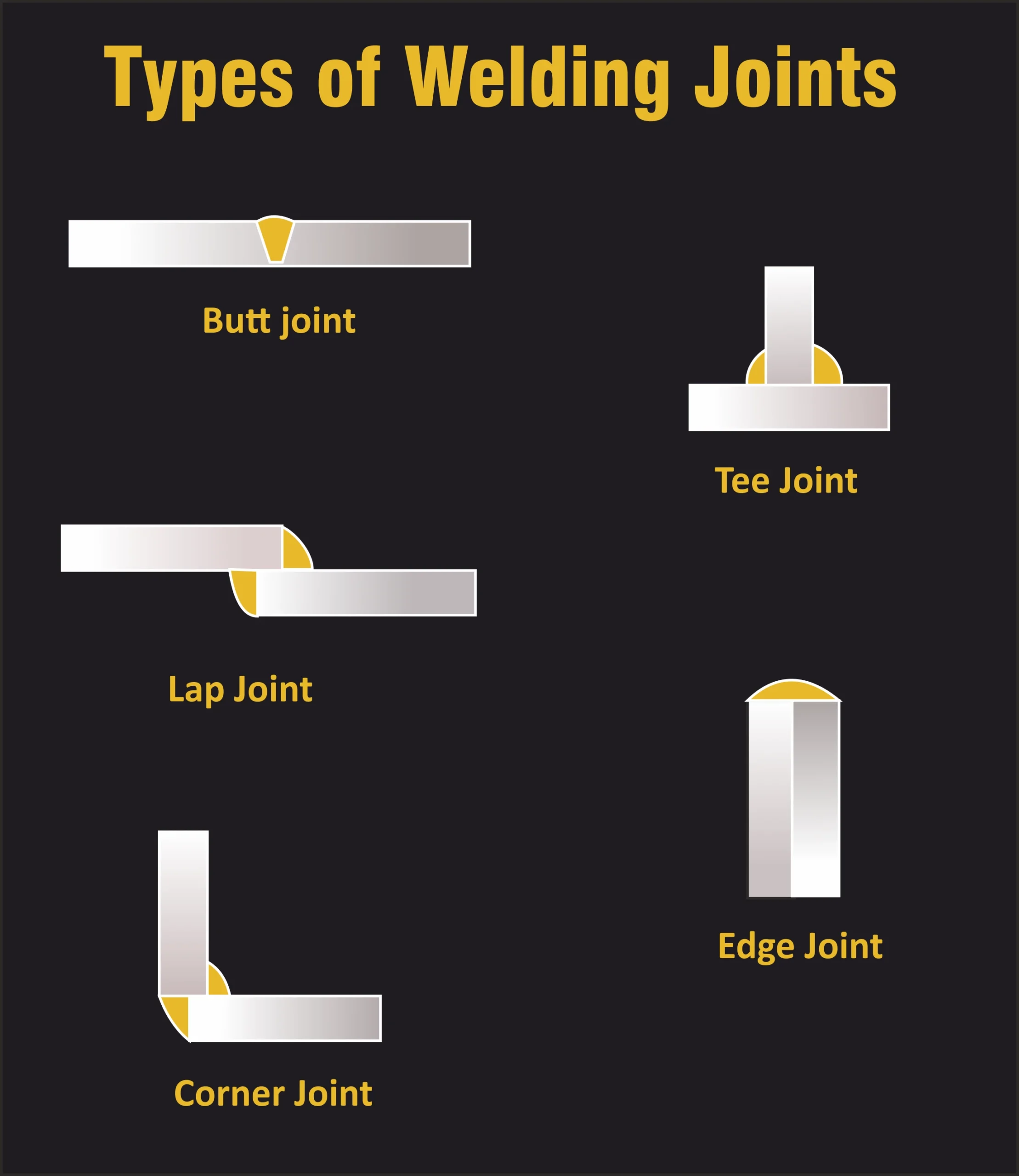

5 Types Of Welding Joints You Should Know About

Welding joints refer to the points where two or more metal pieces are joined together by applying heat, pressure, or a combination of both. From simple butt joints to complex corner joints, the diversity of welding joints allows for versatility in constructing everything from skyscrapers to intricate machinery. Welding joints are fundamental to determining welded assemblies’ strength, durability, and functionality.

Understanding welding joints is as crucial as choosing the right welder involved in fabrication, as they dictate the success and reliability of welded structures.

Basic Types Of Weld Joints Used In Fabrication

There are 5 basic types of welding joints commonly used in fabrication and various welding services, each with its characteristics and applications.

1. Butt Joint

- A butt joint is formed when two pieces of metal are aligned in the same plane and joined together by welding along their adjoining edges.

- It is one of the simplest and most common types of welding joints, suitable for joining flat pieces of metal with minimal thickness variation.

- Butt joints are commonly used in industries such as automotive, construction, and shipbuilding for joining plates, sheets, and structural components with consistent thicknesses.

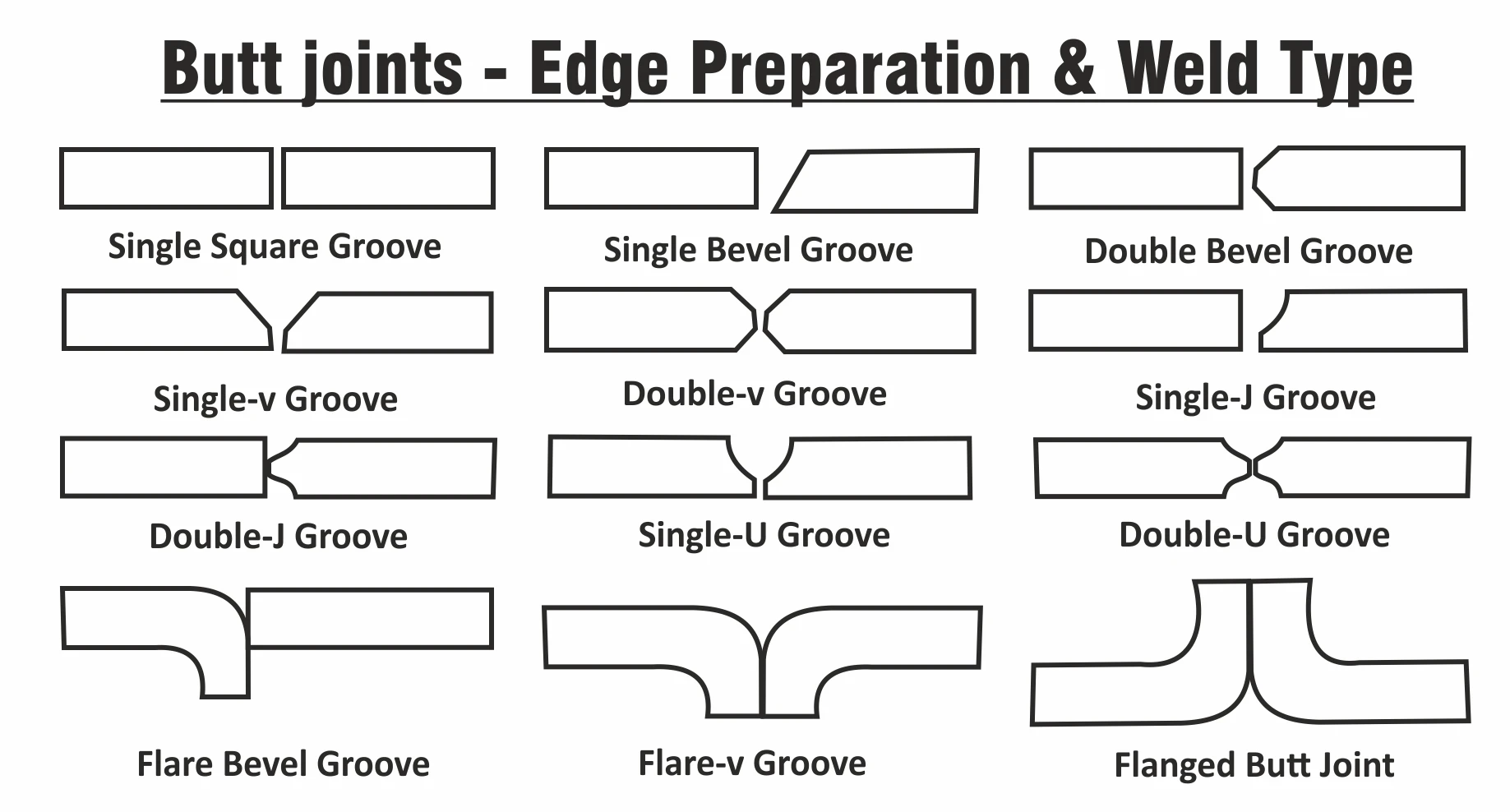

- Edge Preparation –

2. Lap Joint

- In a lap joint, one piece of metal overlaps another, and welding is performed along the edges of the overlap.

- This type of joint provides increased strength and surface area for welding compared to butt joints, making it suitable for joining materials with differing thicknesses.

- Lap joints are widely used in sheet metal fabrication, aerospace engineering, and assembly of structures where flexibility and ease of assembly are essential.

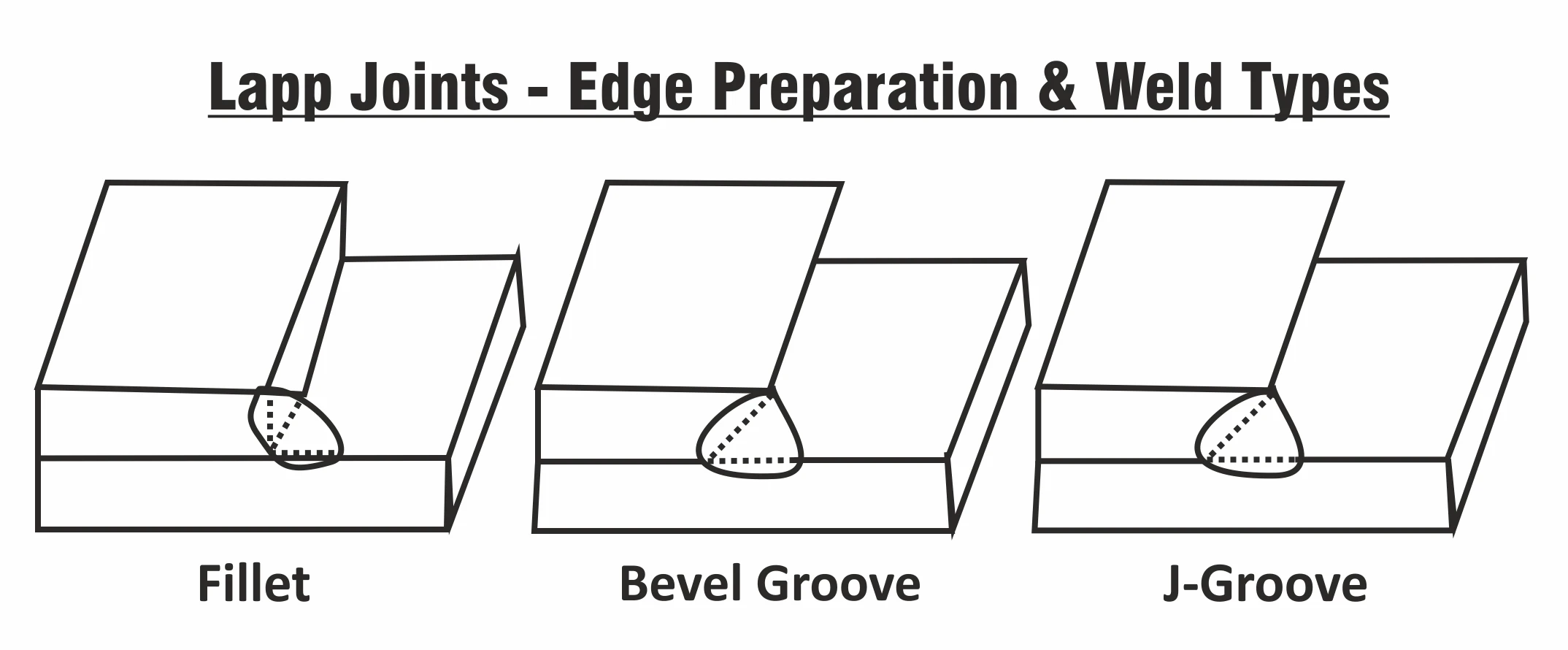

- Edge Preparation –

3. Corner Joint

- A corner joint is formed when two pieces of metal are joined at right angles.

- Welding is typically performed along the edges of the joint, creating a strong connection between the perpendicular surfaces.

- Corner joints are frequently used in constructing frames, brackets, and other structures where stability and load-bearing capacity are paramount.

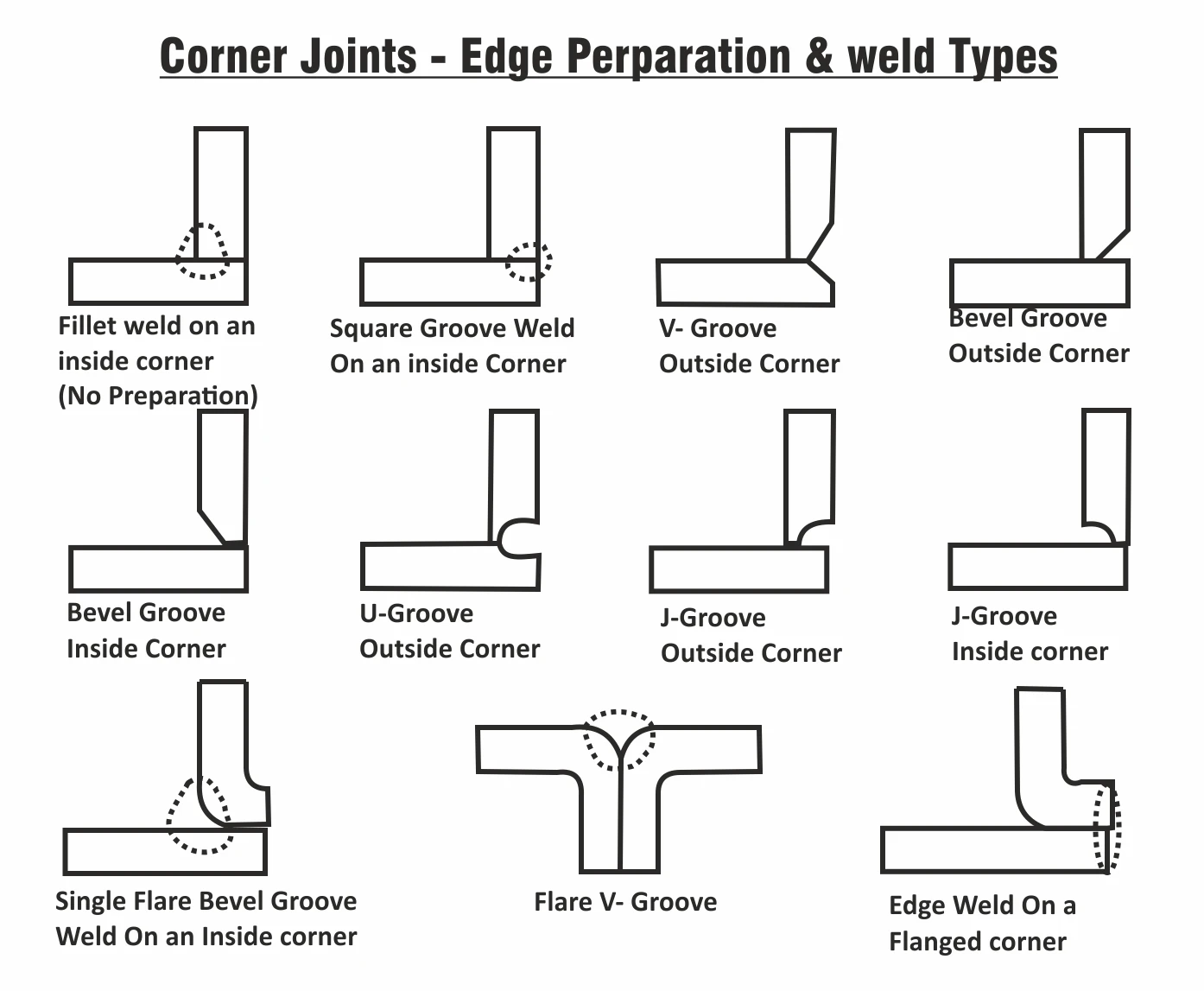

- Edge Preparation –

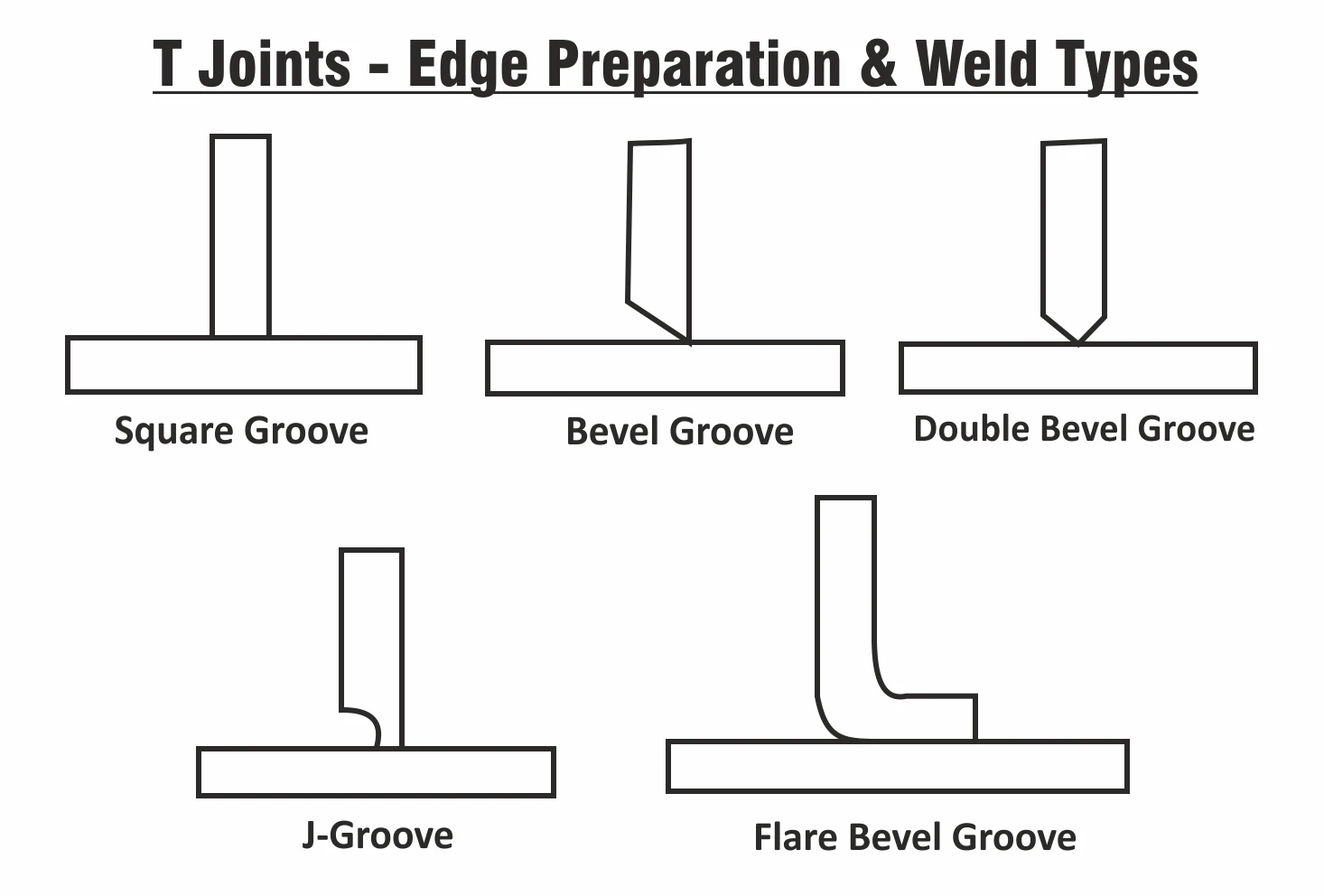

4. Tee Joint

- A Tee or T-joint is created when one piece of metal is perpendicular to another, forming a “T” shape.

- Welding is carried out along the intersecting edges of the joint, ensuring a secure bond between the two components.

- T-joints are commonly used in structural welding, pipe fabrication, and machinery and equipment manufacturing, where two components must be joined at right angles.

- Edge Preparation –

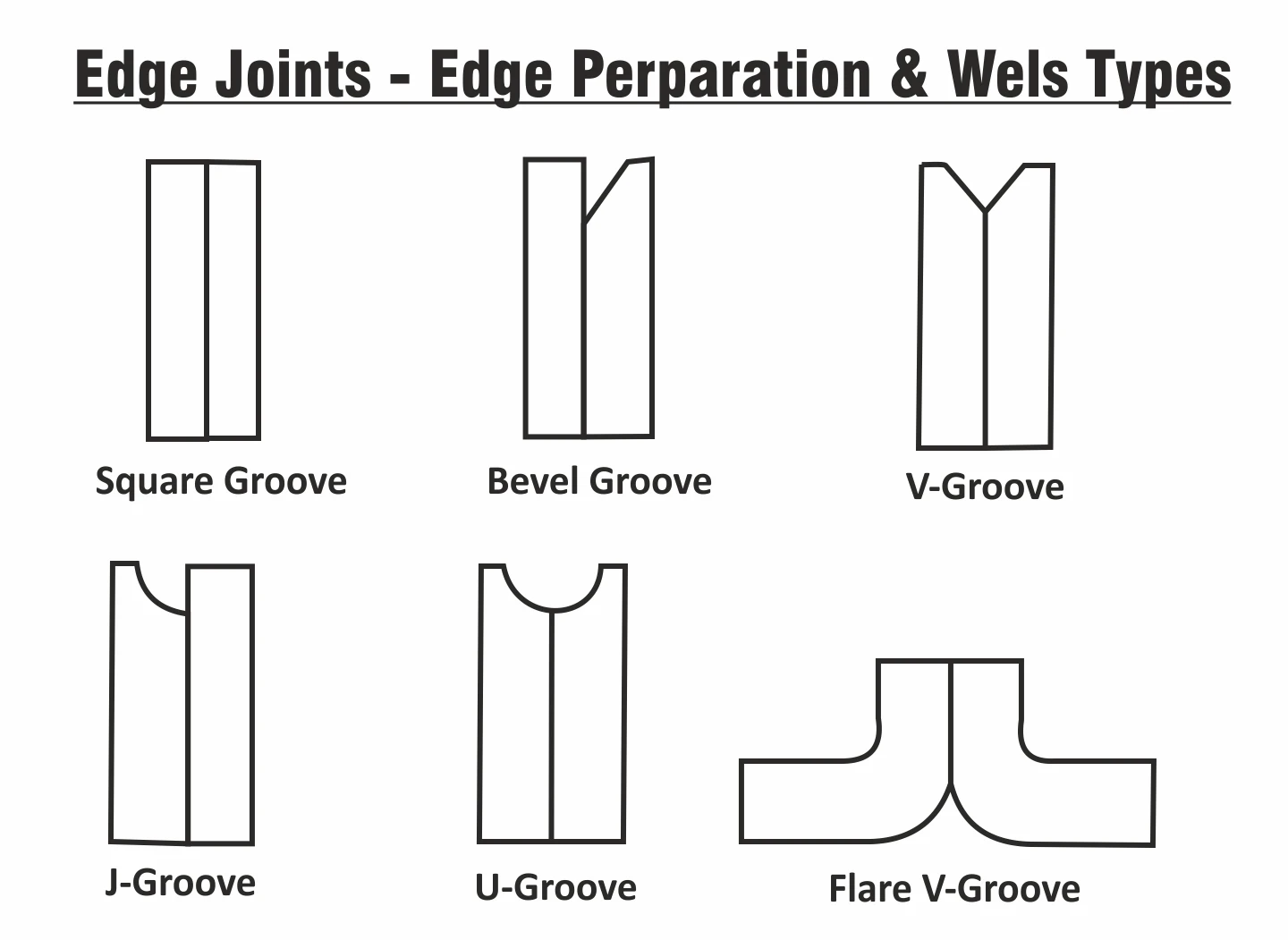

5. Edge Joint

- An edge joint occurs when two pieces of metal are joined along their edges, typically in a single plane.

- Welding is performed along the entire length of the joint, ensuring full penetration and strength.

- Edge joints, such as welding pipes, tubes, and cylinders, are used in applications requiring a continuous seam.

- Edge Preparation –

Manufacturers can ensure and extend the welded structure’s durability, functionality, and safety by selecting the appropriate joint for each application and employing proper welding techniques.

Seamless Welding Solutions For Your Fabrication Projects

Invest in quality craftsmanship that stands strong against the trials of time. Partner with Khalsa Welding Toronto for welding services that guarantee durability, reliability, and peace of mind.

From intricate fabrication projects to heavy-duty repairs, our welding services in Toronto are the backbone of your success.

Contact us today at (416) 809-5335 for impeccable craftsmanship and unparalleled dedication to quality.

RECENT POST

- 6 Key Factors To Consider For Proper Mechanical Piping Insulation

- 5 Types Of Welding Joints You Should Know About

- 7 Common Types Of Welding Services

- How Long Does A Typical Welding Service Take?

- Emergency Welding Repairs: How Mobile Welders Save the Day

- How To Maintain And Extend The Lifespan Of Welded Structures